Experts in optimizing packaging lines

Based on our extensive experience gained within the food, pet care and other industries, the Engilico team is committed to help you to optimize your packaging lines and to improve your sealing quality. Contact us today for more information on how we can assist you to help you solve sealing and packaging issues.

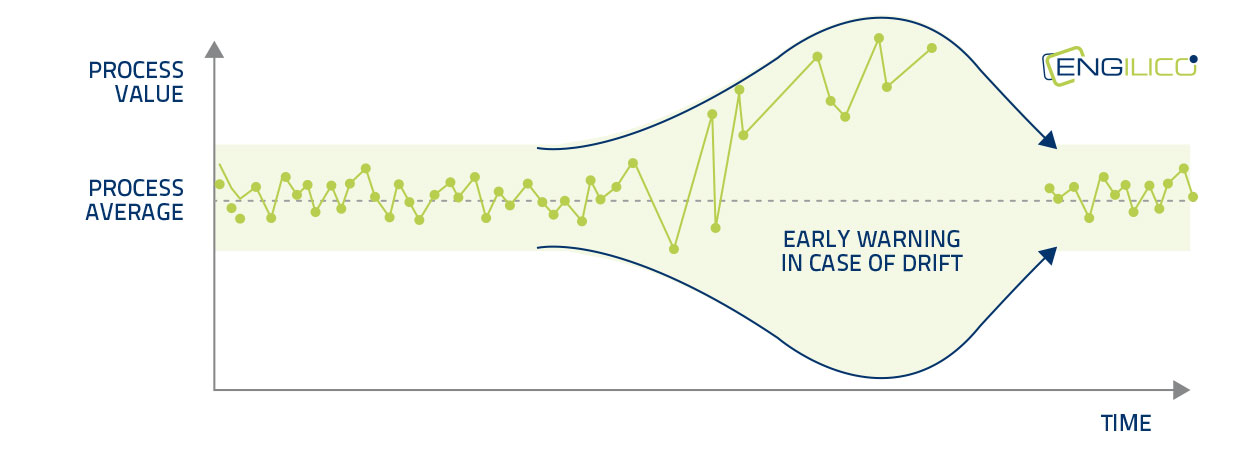

Prior to the deployment of SealScope® the packaging process needs to be audited an improved for optimal sealing quality and speed. Once the process is optimized it can be monitored and inspected.

A typical implementation trajectory of the SealScope® consists of the following steps.

LINE AUDIT

Auditing the line (process) is an essential step in the integration trajectory of SealScope®. The key to better packaging quality and performance lies in optimizing your process. Defective seals are typically caused by a combination of systematical and incidental (statistical) process errors. During a line audit, the SealScope® is used to assess the current status of the production line and to identify root causes of systematical errors.

IMPROVE THE PROCESS

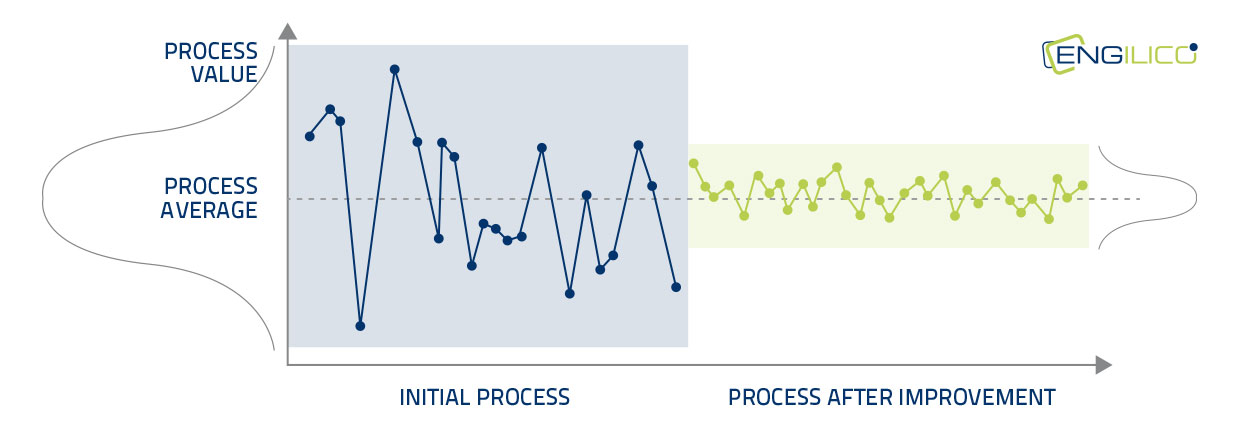

When sources of sealing problems are identified, the process can be improved in order to reduce the variation. SealScope® allows to measure the process variation and can thus be used to quantify the impact of improvements on the line.

Engilico has experienced engineers that can assist the customer during both auditing and improvement trajectories.