Case Studies

At Engilico we strive for zero seal defects and are proud of the results we daily book with our customers. We therefore gladly share a few of our seal integrity and package quality success stories.

ENJOY THE SCENT OF PERFECTLY PACKAGED BATH SALT

Kneipp improves their packaging process with in-line seal inspection

Today we visit the Kneipp® Oberhauser plant near Würzburg with Mrs. Heilscher, responsible for lean manufacturing. In this modern production plant, a wide variety of products are processed, including bath, body care, and even nutritional supplies.

DOWNLOAD PDF

Continue reading →

KEEPING SAVORY SNACKS CRACKLING

In-line hyperspectral seal inspection enables end-of-line automation for packaging snack trays

Since 1949, one of the most popular television and party snacks has been produced in Austria: the thin, salty pretzel sticks from the brand Soletti. Meanwhile Soletti became part of Kelly Snacks, and the successful product of flour, water, salt and yeast is exported to more than 40 countries. To keep up with the continuous growth, Kelly most recently invested in two new production lines for packaging various types of trays. A key element for these salty snacks is to preserve the crispiness, so seal integrity is critical. That’s why Kelly also integrated two new HyperScope® systems into these production lines, for fully automatic and 100% in-line seal inspection of the single- and multi-compartment trays with transparent as well as printed films.

DOWNLOAD PDF

Continue reading →

ENSURING THE HIGHEST QUALITY FOR BABY FOOD PACKAGING

Gittis deploys several production lines with in-line seal inspection and process monitoring

At the foot of the Alps near Salzburg, the Austrian company Gittis is surrounded by a natural environment that inspires every day to produce valuable baby nutrition. The Gittis products are 100% produced in Austria and supplied to customers all over the world. Baby food is delicate, and it is extremely important to meet the highest quality requirements of customers and end-users. As the Asian market, where quality requirements are extremely high, is of great importance, Gittis upgraded all their packaging lines for baby nutrition with 100% in-line seal inspection to guarantee the best packaging quality.

DOWNLOAD PDF

Continue reading →

100% SEAL INSPECTION SPICES UP PACKAGE QUALITY

KOTÁNYI innovates with in-line seal inspection of pouches with spices

What is the perfect recipe for a company that specializes in enhancing food with herbs and spices? Well, you need more than just paprika — you need passion, pioneering spirit, production excellence and an enduring striving for superb quality. Because Kotányi is automating their pouch packaging lines, they recently deployed two innovative, in-line seal inspection systems to assure the quality of their packages with herbs.

DOWNLOAD PDF

Continue reading →

INNOVATING FOR BETTER PACKAGING OF BAKERY MIXES

Puratos relies on SealScope seal inspection for packaging lines of O-tentic sourdough mixes

Delicious bread is a favored element in the daily food consumption of millions of people. Bread is typically prepared with high-value bakery mixes that consist of living ingredients such as yeast. As these need to be protected from oxidation and moisture, the packaging must be perfectly sealed. That’s why Puratos has equipped their Vertical-Form-Fill-Seal packaging machines with a SealScope® in-line seal inspection system.

DOWNLOAD PDF

Continue reading →

In-line, 100% seal inspection leads to better packaging quality and productivity

The sealing of flexible packages is a critical phase in the packaging process for many food manufacturers. Wrinkles, folds, and product in the sealing area are the main causes of leaking packages. As food products are often packed under modified atmosphere conditions, even the smallest leaks reduce shelf life, induce changes in taste, pose health risks, and may also lead to expensive re-calls with potential brand damage. Engilico offers solutions for inline, 100% seal inspection of flexible packages enabling customers to realize better packaging quality, higher productivity, and elimination of manual inspection.

DOWNLOAD PDF

Continue reading →

Focus on cheese packaging quality

Flanders Food Productions deploys second SealScope® seal inspection system on new cheese packaging line

For a delicate product such as cheese, the packaging must be perfectly sealed to guarantee shelf life. That’s why Flanders Food Productions has again equipped their newest sliced cheese packaging line with an Engilico in-line seal inspection system.

DOWNLOAD PDF

Continue reading →

Supporting the drive for less plastic

HyperScope also inspects packages with cardboard trays or backing

Today, there is a definitive trend to use less plastic in packaging for fresh meat, fish, cheese. Formable paper or cardboard backings sealed with plastic film reduce up to 80% of plastic, are made of recyclable materials and interesting for marketing as they can be printed in attractive patterns.

DOWNLOAD PDF

Continue reading →

Application case: SMART SEAL INSPECTION OF FRESH PRODUCE

The sealing of flexible packages is a critical phase in the packaging process for fresh produce manufacturers. Wrinkles, folds, and product in the sealing area are the main causes of leaking packages. As fresh produce is often packed under modified atmosphere conditions, even the smallest leaks reduce shelf life, induce changes in taste, pose health risks, and may also lead to expensive re-calls with potential brand damage.

DOWNLOAD PDF

Continue reading →

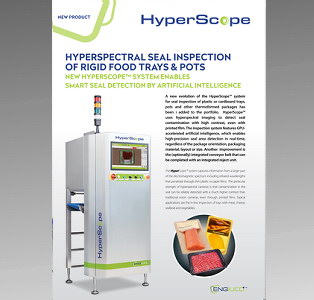

Application paper: HYPERSPECTRAL SEAL INSPECTION OF PLASTIC FOOD TRAYS & THERMOFORMING

INNOVATIVE IMAGING TECHNOLOGY EASILY DETECTS SEAL CONTAMINATION, EVEN THROUGH PRINTED FILMS

Contamination in the seal of rigid plastic packages causes important issues for food producers as it may lead to leakage and consequently reduced shelf life, health issues and even expensive recalls with potential brand damage. As such automatic detection of contaminated seals is important for both food safety and production automation. Engilico, specialist in in-line seal inspection for flexible packaging, now introduces its newly developed seal inspection solution for rigid trays, pots and thermoforms sealed with plastic film.

The HyperScope® solution is based on hyperspectral imaging (HSI). This technology enables to obtain images with much higher contrast than traditional vision systems and can even detect contamination through printed films. Typical applications are the in-line inspection of trays with meat, cheese, fruits, ready meals, snacks, etc.

DOWNLOAD PDFGB Foods (Continental Foods) implements seal inspection for pouch packages with powder mixes

More than 100 years ago, Jeanne Verelst created the first Belgian recipe for powdered pudding preparation. Today, powdered desserts are still a classic in the Continental Foods range and millions of units are packed every year on state-of-the-art packaging machines. For the automated, 100% quality control of the seals of the pouches, Continental Foods recently switched from vision-based control to SealScope® in-line seal inspection.

DOWNLOAD PDFSpecial Dog Company innovates with inline seal inspection of retort pouches for wet pet food

Wet pet food manufacturing is a complex process to consistently guarantee a top quality, healthy and tasty product. Incompletely sealed packages result in contaminating machines, lost production and labor time for cleaning, manual sorting of bad packages, etc. If these badly sealed packages leave the production site, the impact can be even greater, with potential risk for expensive product returns, call backs and brand damage.

And that’s why Special Dog Company invested in a 100% inline seal inspection to guard the quality of the seals.

Excellent packaging quality for freshly made pâté

De Spiegeleire implements SealScope® 100% seal inspection on pâté packaging line

Retailers always impose higher quality requirements on suppliers of freshly packed products. When packaging food – often under atmospheric modified conditions, leaking or open packaging must be prevented to ensure preservation and food safety. That is why De Spiegeleire N.V., a Belgian producer of quality pâtés, implemented the SealScope ® seal inspection system to automatically check their pâté in consumer packaging.

Seeberger increases packaging quality and line output using SealScope®

Seeberger is the leading brand of premium nuts and dried fruit in Europe. These products require gas flushed packages to make sure that the product quality and flavor are preserved. To improve their packaging quality and productivity, Seeberger deployed SealScope®, Engilico’s inline seal inspection and monitoring technology.

DOWNLOAD PDF

Seeberger is the leading brand of premium nuts and dried fruit in Europe. These products require gas flushed packages to make sure that the product quality and flavor are preserved. To improve their packaging quality and productivity, Seeberger deployed SealScope®, Engilico’s inline seal inspection and monitoring technology.

DOWNLOAD PDF

Continue reading →

SCHOEPS controls output quality of grated cheese bags with SealScope®

When SCHOEPS appointed a new general management in 2018, one of the first objectives was to increase outgoing product quality. With the company’s vision to deliver premium quality cheese products to their worldwide customers, they opted for SealScope® to 100% inspect their grated cheese bags for defective seals. As a result, the number of compromised outgoing products reduced drastically, to almost zero.

DOWNLOAD PDFContinue reading →

Hazeleger monitors packaging quality using SealScope®

Cheese packed with care

Cheese packed with care

When introducing a new type of package, Hazeleger Kaas optimized the performance of its horizontal flow wrap machines by deploying SealScope®, Engilico’s in-line seal inspection and monitoring technology. Since the integration of the SealScope® solution, the packaging line speed and the outgoing packaging quality are maintained at the highest level.

DOWNLOAD PDFContinue reading →

Machland: excellent outgoing package quality

SealScope checks in-line, in a non-destructive way 100% of the packages. Wrinkles and product in seal are easily detected and can be excluded via a rejection unit. In addition, SealScope continuously monitors the sealing process, providing early warning in case of process drift. DOWNLOAD PDF

Handl Tyrol invests in SealScope® for stricter quality control on outgoing products

According to Handl Tyrol, SealScope® is one of the greatest innovations in the packaging industry in recent years. SealScope® enables Handl Tyrol to increase their packaging quality and process productivity.

DOWNLOAD PDF

According to Handl Tyrol, SealScope® is one of the greatest innovations in the packaging industry in recent years. SealScope® enables Handl Tyrol to increase their packaging quality and process productivity.

DOWNLOAD PDF

Lutèce: monitoring & inspection technology on pouch packaging line

DOWNLOAD PDF

Marcassou focuses on package quality

Using SealScope® Marcassou has increased its outgoing quality of its HFW line by reducing the number of compromised packages that leave the production line by over 90%.

DOWNLOAD PDF

Using SealScope® Marcassou has increased its outgoing quality of its HFW line by reducing the number of compromised packages that leave the production line by over 90%.

DOWNLOAD PDF

Friesland Campina increases packaging speed and monitors seal quality

The SealScope® automatic quality inspection has reduced the risk of open packages by over 90%. Additionally, SealScope®’s monitoring ability has enabled a packaging speed increase of 30% while guaranteeing package quality, deferring the investment in an extra packaging line.

The SealScope® automatic quality inspection has reduced the risk of open packages by over 90%. Additionally, SealScope®’s monitoring ability has enabled a packaging speed increase of 30% while guaranteeing package quality, deferring the investment in an extra packaging line.Kaasbrik invests in end-of line automation

Kaasbrik has invested over 2 Meuro in end- of-line automation of its grated cheese production line over the last year. SealScope® has successfully replaced manual inspection of seal quality. The monitoring abilities assist the operators to keep the line in top shape.

DOWNLOAD PDF

Kaasbrik has invested over 2 Meuro in end- of-line automation of its grated cheese production line over the last year. SealScope® has successfully replaced manual inspection of seal quality. The monitoring abilities assist the operators to keep the line in top shape.

DOWNLOAD PDF