KOTÁNYI innovates with in-line seal inspection of pouches with spices

What is the perfect recipe for a company that specializes in enhancing food with herbs and spices? Well, you need more than just paprika — you need passion, pioneering spirit, production excellence and an enduring striving for superb quality. Because Kotányi is automating their pouch packaging lines, they recently deployed two innovative, in-line seal inspection systems to assure the quality of their packages with herbs.

DOWNLOAD PDF

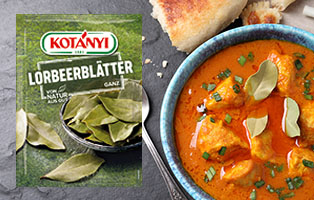

Spice pouches full of flavors

Kotányi supplies their herbs in different packaging formats for retail and gastronomy business: classic glass or plastic jars, mills, and pouch packages. The packaging design and materials are subject to continuous development and improvement. Eg. for the spice pouches, by leaving out a single layer of plastic, Kotányi was able to considerably reduce the packaging waste. Customers can always rely on the proven quality of Kotányi herbs and spices. The strictest quality controls and compliance to the highest standards such as ISO 9001:2015 and IFS Food 6.1 ensure that the freshness and aroma is retained for a long time.

Kotányi supplies their herbs in different packaging formats for retail and gastronomy business: classic glass or plastic jars, mills, and pouch packages. The packaging design and materials are subject to continuous development and improvement. Eg. for the spice pouches, by leaving out a single layer of plastic, Kotányi was able to considerably reduce the packaging waste. Customers can always rely on the proven quality of Kotányi herbs and spices. The strictest quality controls and compliance to the highest standards such as ISO 9001:2015 and IFS Food 6.1 ensure that the freshness and aroma is retained for a long time.

“One important aspect of the pouch quality is a perfect sealing to preserve the highest quality and excellent taste.”, adds Herr Bernhard Brenner, Plant Manager at Kotànyi, “For this purpose, Kotányi opted for SealScope® seal inspection, more specifically for their packaging lines of bay leaves and cinnamon sticks.”

Success based on the latest production technology: Enter SealScope®

For the packaging of pouches, Kotányi uses rotative Laudenberg and SN packaging machines. First the pouch is made from packaging film, by sealing three sides. Next the pouches are filled with herbs and sealed at the top. Initially operators manually verified the individual packages, but as Kotányi aims at production excellence by automating the packaging lines, altogether with the fact that operators are always more difficult to hire, it was clear that an automated inspection solution was required. Also, it is nearly impossible to manually check the sealing with constant focus and high accuracy.

Kotányi learned about the automated, in-line SealScope® solution through their packaging machine manufacturer. The innovative SealScope® system uses sensors mounted on the sealing bars to verify whether there are product or folds in the seal which can lead to open packages. Every produced package is instantly compared to a good reference seal and when errors in the seal are detected, the defective packages are automatically removed from the conveyor belt by an ejection system. As herbs are expensive, the rejected products are reworked, so there is no production waste and yet the best quality is ensured.

Two packaging lines for bay leaves and for whole cinnamon sticks are equipped with SealScope®. These are relatively solid, rigid herbs that will certainly cause a seal breach when stuck in the seal. Also, because the herbs are large, there is an increased probability that during the filling and sealing, product is stuck in the sealing area. Even when the seal is not breached, product in seal is not acceptable for cosmetic reasons. Besides inspecting for product in seal, SealScope® also detects folds or plies in the sealing area which can also lead to open packages. This is equally important to avoid that the spices lose their aromatic qualities.

Two packaging lines for bay leaves and for whole cinnamon sticks are equipped with SealScope®. These are relatively solid, rigid herbs that will certainly cause a seal breach when stuck in the seal. Also, because the herbs are large, there is an increased probability that during the filling and sealing, product is stuck in the sealing area. Even when the seal is not breached, product in seal is not acceptable for cosmetic reasons. Besides inspecting for product in seal, SealScope® also detects folds or plies in the sealing area which can also lead to open packages. This is equally important to avoid that the spices lose their aromatic qualities.

Another important function of SealScope® is the monitoring of the packaging process. Because each package is measured, it is also possible to register trends and deficiencies in the production process. With the spices and herbs, there are often residues contaminating the sealing bars. In this way, if the rejection ratio increases, the packaging can automatically be paused and maintenance can be done. Or the machine can be timely adjusted, which can prevent production of bad packages and production delays.

Remote support helps to quickly solve issues

Kotányi is delighted with the professional cooperation during the deployment of the project, especially as this coincided with the corona pandemic. In an initial visit, all specifications and dimensions of the packaging machines were registered to manufacture the sensor brackets and configure the electronics for the controller cabinets. Soon after, the system was successfully deployed and operators were trained.

A valuable benefit that became apparent was the capability to adapt the SealScope® installation from within Engilico’s headquarters. As such, unforeseen issues, software upgrades or system fine-tuning can be efficiently addressed without wasting time and money by avoiding the need for local support visits.

Further focus on automation

As Kotányi is increasingly automating the production and packaging, in-line seal inspection will continue to play an important role in further upgrades of packaging lines, also for grinded spices. “Kotányi is definitely pleased with the automated seal inspection” concludes Herr Brenner, “Superb quality and safety are what we are all about, and SealScope® fits perfectly within this philosophy.”

DOWNLOAD PDF