Gittis deploys several production lines with in-line seal inspection and process monitoring

At the foot of the Alps near Salzburg, the Austrian company Gittis is surrounded by a natural environment that inspires every day to produce valuable baby nutrition. The Gittis products are 100% produced in Austria and supplied to customers all over the world. Baby food is delicate, and it is extremely important to meet the highest quality requirements of customers and end-users. As the Asian market, where quality requirements are extremely high, is of great importance, Gittis upgraded all their packaging lines for baby nutrition with 100% in-line seal inspection to guarantee the best packaging quality.

DOWNLOAD PDF

Export imposes stricter quality requirements

It was more than a decade ago that China was confronted with an immense scandal after several infants died because of melamine contamination in Chinese baby milk powder. This caused a huge demand for European products as there was a lot of distrust in the locally produced milk powders. More recently, other problems arose when fraudulent organizations mixed cheap baby food with products from renowned brands and sold this mixture under the original brand. With the huge import of baby food and to avoid further scandals, also Chinese quality requirements drastically increased. As costs associated with packaging quality issues, such as recalls and brand damage, are extremely high, Gittis extended their manufacturing process with in-line seal inspection.

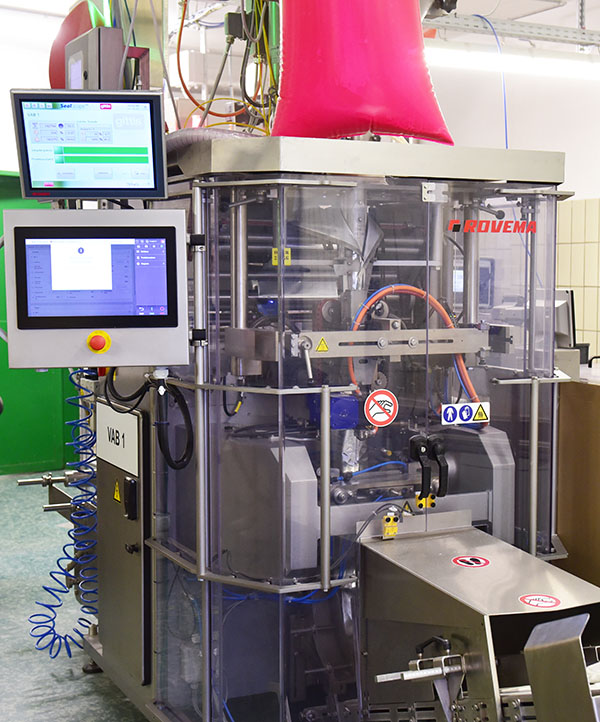

Gittis packages baby food powder in aluminum foil bags on ROVEMA VFFS (Vertical-Fill-Form-Seal) packaging lines. A perfect seal is critical as the baby food is packed under modified atmosphere conditions. The transport from factory to end customer is often exposed to harsh conditions. For the Asian markets, the goods are travelling several months in varying temperatures and subject to vibrations and shocks over thousands of miles on sea and land routes. Even the slightest leak will spoil the content resulting in possible customer complaints, high return costs and brand damage. With a daily production of over 90.000 bags, it is impossible to manually check every package. For optimal secondary packaging, the bags have tuck-ins and the multiple layers of foil need to be perfectly sealed. At high packaging speeds, it occurs that the foil is not ideally positioned during the filling, which can cause an imperfect seal and potentially leaking product.

Better process control through in-line seal inspection

As Gittis is driven by continuous improvement, they were looking for better and automated methods to inspect the product for potential leaks. They learned about SealScope® through another premium Austrian food producer. After a positive evalaution, Gittis equipped their Rovema VFFS machines with SealScope® in-line seal inspection. The innovative SealScope® system uses sensors mounted on the sealing bars to verify whether there are defective seals which can lead to open packages. Every produced seal is instantly compared to a good reference seal and faulty packages are automatically rejected. The most common seal defects are plies or folds caused by the aluminum-based foil that is not correctly positioned during the sealing phase. Another seal defect example is product that is stuck in the sealing area which can also lead to badly sealed and open packages.

A major benefit of SealScope®, which also fits in with Gittis’ philosophy of continuous improvement, is the process control and monitoring function. In case of consecutive errors – e.g. due to plies or folds of the foil, or synchronization problems during dosing and bag filling – the packaging process is halted, and operators are timely alarmed so they can quickly investigate the cause of the fails and take immediately corrective actions. This is extremely important to avoid issues with rework, sorting bad packages and unnecessary material costs. As an example, SealScope® was crucial to timely detect poor quality foil rolls that were supplied with pre-existing folds.

A major benefit of SealScope®, which also fits in with Gittis’ philosophy of continuous improvement, is the process control and monitoring function. In case of consecutive errors – e.g. due to plies or folds of the foil, or synchronization problems during dosing and bag filling – the packaging process is halted, and operators are timely alarmed so they can quickly investigate the cause of the fails and take immediately corrective actions. This is extremely important to avoid issues with rework, sorting bad packages and unnecessary material costs. As an example, SealScope® was crucial to timely detect poor quality foil rolls that were supplied with pre-existing folds.

“We are very satisfied with SealScope®, especially the process control is a huge benefit.”, says Mr. Kalchhofer, Director Operations, “Since the use of this efficient in-line inspection system, our complaints have been drastically reduced. It is a smart investment, as the system quickly pays for itself.”

Excellent cooperation

Gittis is delighted with the professional cooperation during the installation and the daily use. More specifically, the remote support is a valuable functionality, allowing the SealScope® systems to be managed from within Engilico’s HQ support center. As such, unforeseen issues, software upgrades or system fine-tuning can be efficiently addressed without wasting time and money on local support visits.

Long-term cooperation with suppliers and partners is an important element in Gittis’ company values. Because of the excellent cooperation, Gittis has also already hosted several other potential customers in their production facilities to witness the state-of-the-art in-line seal inspection solution.

DOWNLOAD PDF