Wet pet food manufacturing is a complex process to consistently guarantee a top quality, healthy and tasty product. Incompletely sealed packages result in contaminating machines, lost production and labor time for cleaning, manual sorting of bad packages, etc. If these badly sealed packages leave the production site, the impact can be even greater, with potential risk for expensive product returns, call backs and brand damage.

And that’s why Special Dog Company invested in a 100% inline seal inspection to guard the quality of the seals.

Established in 2001, Special Dog Company is today one of the 4 most significant pet food producers in Brazil, selling in the Brazilian market and 11 other countries. In 2019, the company deployed an ultra-modern wet pet food factory to increase the product portfolio to keep growing in the market.

“The sealing of flexible packages is a critical phase in the packaging process.”, says Octávio Soberón, Manager of Wet Pet Food Division. ”Even with a top quality packaging machine, bad sealings could occur from time to time.” Defective seals are often caused by wrinkles, folds, or product in the sealing area and lead to open or leaking packages.

Wet pet food is especially prone to sealing concerns. Because many glutinous sauces or gels are used in the recipes, it easily can stick in, or around the package’s sealing area during the filling process

Badly sealed pouches are a major concern during the sterilization process, as when the pet food is heated, it might leak and pollute the autoclave. The disruption to production and man-hours for autoclave cleaning has a domino effects in cost. Worse, if compromised packages are not detected they can lead to reduced shelf life, liability for health risks, and broad re-calls.

“Packaging is also responsible for making sure the product gets from the factory, through transport and distribution, and on to retail and the home without any loss to the integrity of the product. At the latter end it may also be responsible for providing barriers to oxidation and moisture migration which can affect palatability and the nutritional composition of the product.”

100% seal inspection

Delivering quality products is one of Special Dog Company’s corporate values. This requires investment in top equipment, well trained people and refined quality procedures. Special Dog Company is certified with many international quality standards and this vision of quality has also resulted in multiple awards as Best Workplace in Latin-America in 2019. Maintaining quality at the highest level also needs continuous improvement in quality procedures and equipment.

For the packaging of the wet pet food, Special Dog Company deployed a Toyo Jidoki rotary pouch packaging machine. To inspect the sealing of the retort pouches, Special Dog Company extensively researched the market and finally they opted for SealScope®, the in-line seal inspection system.

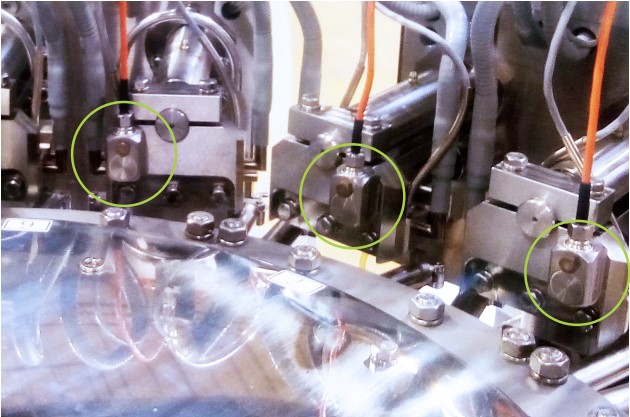

SealScope® offers a unique approach for in-line seal inspection. Dedicated sensors are retrofitted on the sealing jaws of the dual-lane rotating packaging machine at two stations in the carrousel.

The sealing bars of the rotary packaging machine are equipped with SealScope® sensors that detect product in seal, wrinkles and folds that cause leaking packages.

During the closing of the sealing jaws, the response is measured and compared to a reference model of correctly sealed packages. When the deviation is higher than a user defined limit – whether the cause is from product in seal, wrinkles, or folds in the seals – the package is rejected. This automated, 100% inspection leads to immediate benefits: Every single package is inspected, so manual inspection can be reduced or drastically reduced. By rejecting the defective packages, the outgoing quality is instantly increasing.

“The non-destructive seal testing made directly on the sealing bars greatly improved our effective line efficiency from previous manual inspection methods.” continues Octávio. As it is needed to comply to their internal statistical quality control standards, Special Dog Company still maintains a random sampling for physical inspection process, but with a much lower number of samples than before. These random samples undergo destructive burst testing amongst other human inspections, requiring 5 to 6 minutes per package.

“The main benefit of SealScope in-line seal inspection is to have a good night of dreams, instead of dealing with quality nightmares.” Mr Sobéron continues, “Special Dog Company is delivering a 100% inspected product, which means satisfied consumers.”

Optimizing the packaging process

As SealScope® inspects every product, it also serves a continuous monitoring system, not only for the sealing process but indirectly for the complete packaging line. When the repeatability of sealing process is varying, this indicates systematic errors in the packaging process.

The system generates user defined warnings, so the operator can take preventive corrective actions – for instance cleaning of the sealing station, replacement of the Teflon protection foils, etc. As such SealScope® helps to avoid further process drift and to keep the machine in optimal shape.

SealScope® also enable to optimize the productivity of the packaging process. Often packaging machines run either too slow (to get acceptable quality) or too fast (with an adverse effect on quality). Using SealScope®, one can determine the optimal machine speed where production output and package quality are maximized.

With the ever increasing demand for high quality wet pet food, Special Dog Company plans to further extend their production capacity. Octávio concludes: “For the installation of the new line, Engilico’s SealScope® system is going to be there, for sure.”

DOWNLOAD PDF