100% Seal Inspection for better flexible packaging results

WHAT IS SEALSCOPE®?

SealScope® is a patented, in-line solution for 100% seal inspection and monitoring of your sealing process. SealScope’s main functionalities are:- Detection and rejection of compromised packages due to wrinkles or product in seal

- Optimization of your packaging process for higher outgoing packaging quality and higher packaging equipment performance and availability

- Monitoring of your sealing process and issuing alarms when exceeding user defined thresholds

- Logging and visualization of production data

SealScope® is compatible with almost all packaging machines producing flexible packaging types including pillow bags, flow packs and pouches and can verify up to 500 packages per minute.

Using the detection and monitoring tools of SealScope®, the outgoing number of packages with defective seals can be reduced by a factor of 10 or more (*). Additionally, the overall packaging machine effectiveness can be increased while monitoring the sealing quality.

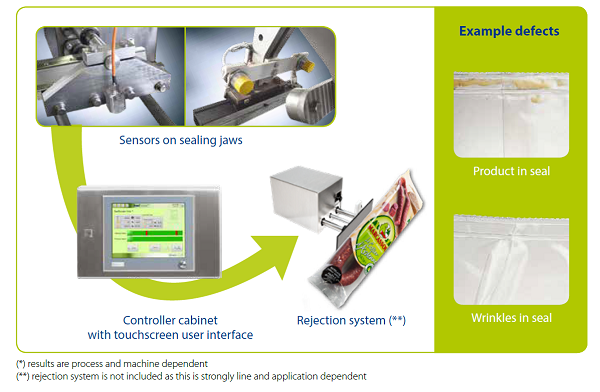

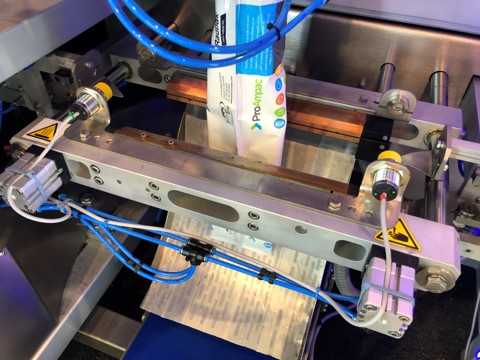

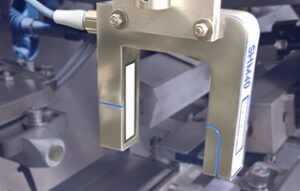

SEALSCOPE® LAYOUT

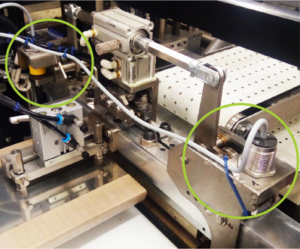

SealScope® consists of one or multiple sensors, a controller cabinet with touchscreen and the intuitive SealScope® software.

SEALSCOPE® WORKING PRINCIPLE

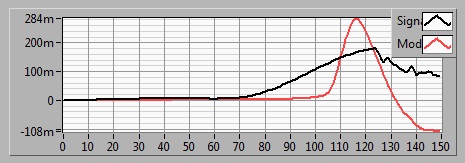

SealScope® checks every seal by measuring the sensor signal(s) during the closing of the seal bars and comparing them with a reference model.

In case the difference is higher than the user defined limit, SealScope® will issue a rejection signal.

The reference models are automatically updated at the start of every run using correct seal profiles (base lining).

SealScope® can use different reference models to accommodate changes in thickness, material, weight or size.

SealScope® operator view

Good seal

Bad seal

SEALSCOPE® BENEFITS

![]() INCREASING PACKAGING LINE PERFORMANCE AND AVAILABILITY

INCREASING PACKAGING LINE PERFORMANCE AND AVAILABILITY

Often packaging machines run either too slow (to get acceptable quality) or too fast (with adverse effect on quality).

With SealScope® you can determine the optimal machine speed where production output and package quality are maximized. Additionally, rejection of open packages will reduce downstream contamination and standstills.

| INCREASING PACKAGING QUALITY Detection and rejection of compromised seals results in higher outgoing quality. This means longer shelf life, higher customer satisfaction and ultimately a stronger brand image. |

|||

| END-OF-LINE AUTOMATION SealScope® enables safe end-of-line automation by automating the seal inspection process. |

|||

| ELIMINATING MANUAL INSPECTION SealScope® allows the replacement of manual verification by 100% automated seal inspection. |

|||

| UNIFORMIZING PRODUCTION PERFORMANCE By comparing SealScope® data from various operators and machines, a better overall production performance can be achieved. |

|||

| OPTIMIZED MACHINE OPERATION By verifying the bad packages, the root cause of rejection can be faster determined. This makes it easier for operators and maintenance to keep the machines in optimal operation conditions. |

SEALSCOPE® APPLICATIONS

Pouch packaging

Pouches are more and more popular and available in different types and materials. Also perfect for retort applications They are packaged on rotary or horizontal pouch packaging machines. Example applications are powder, juices, sauces Its main field of application includes loose products, granulated products or doughy products.

SealScope® setup

Application video

Typical products

Powders, pellets, vegetables, fruits, sauces, pet food, etc

Customer references

Supported machine brands

The SealScope® system is adaptable to most heat sealing packaging processes and as such independent of the machine brand. On pouch packaging machines, Engilico has e.g. installations on e.g. SN Packaging, Toyo Jidoki, LeePack, HDG, MesPack, VolPak.

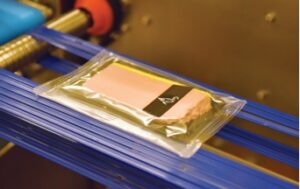

Flow wrap packaging

Flow wraps also called flowpacks or HFW are suited for packaging a wide variety of products often in MAP conditions either separately or on a tray. It’s ideal for packaging single items such as sliced cheese, meat products, breads, pasta etc.

SealScope® setup

Application video

Typical products

Sliced cheese, sliced meats, sausages, pasta, bread, tortillas, cereal bars, etc

Customer references

Hazeleger Kaas, De Spiegeleire Pâte, Flanders Food Productions

Supported machine brands

The SealScope® system is adaptable to most heat sealing packaging processes and as such independent of the machine brand. On Flow wrappers, Engilico has e.g. installations on: e.g. Omori, Fuji, Ilapack, CFS and more.

Pillow bags packaging

Pillow bags are made through VFFS packaging. Form/Fill/Seal packing machines use a single film coil to obtain a package with three weldings : two cross-weldings and one longitudinal welding. Its main field of application includes loose products, granulated products or doughy products.

SealScope® setup

Application video

Typical products

Grated cheese, cereals, chips, powders, pellets, vegetables, powder, fruits, sauces, pet food, etc.

Customer references

Schoeps, KaasBrik, SeeBerger, Machland

Supported machine brands

The SealScope® system is adaptable to most heat sealing packaging processes and as such independent of the machine brand. On Vertical Form fill Seal machines, Engilico has e.g. installations on e.g. UVA, BW Flexible systems, GEA, PFM, InnoTech and more.

SEALSCOPE® REPORTING

-

Visualization of production data

SealScope® logs hourly production data to visually compare performance over various operators, products and packaging lines.

-

Logging of production data

SealScope® logs date, time, total packages, number of good/bad packages per product type.

This data is available in .txt-format for offline statistical analysis.

-

OPC / MQTT

All measurement data can be shared to the company network via OPC/MQTT connectors.

This allows big data analysis & processing to monitor the line performance.

-

Audit trail

Operator interactions with SealScope® are logged to obtain 100% traceability.

SEALSCOPE® Options

Thanks to the open system architecture of SealScope®, other measurement sensors can be integrated for seal inspection and monitoring. Following options in SealScope® are available:

Download Longitudinal Seal Monitoring flyer